Sunday Runday

On this weekly column, Android Central Wearables Editor Michael Hicks talks concerning the world of wearables, apps, and health tech associated to working and well being, in his quest to get sooner and healthier.

This weekend, I flew to Plano, Texas, to take a look at Ultrahuman’s new manufacturing facility. After they walked me by way of each official step of the method, I slipped on some gloves and began making a sensible ring by hand. And it gave me a brand new appreciation for my very own sensible ring.

Sensible rings aren’t designed to be taken aside and put again collectively like different tech. You may know what sensors are inside, however you most likely do not know what else is sitting inside all that titanium, resin, and ceramic, and what determines how thick these rings are. Ring makers do not essentially need you to consider what’s inside.

However with Ultrahuman’s Ring Air within the midst of a gross sales and patent struggle with the Oura Ring, the corporate determined to indicate off its new American manufacturing facility. This had the good aspect impact of lastly sating our curiosity about how sensible rings are made, one thing different manufacturers have been reluctant to speak about previously.

Plus, I get to brag that I “made” a sensible ring, even when they might solely allow us to end sure elements of the method.

How sensible rings are made

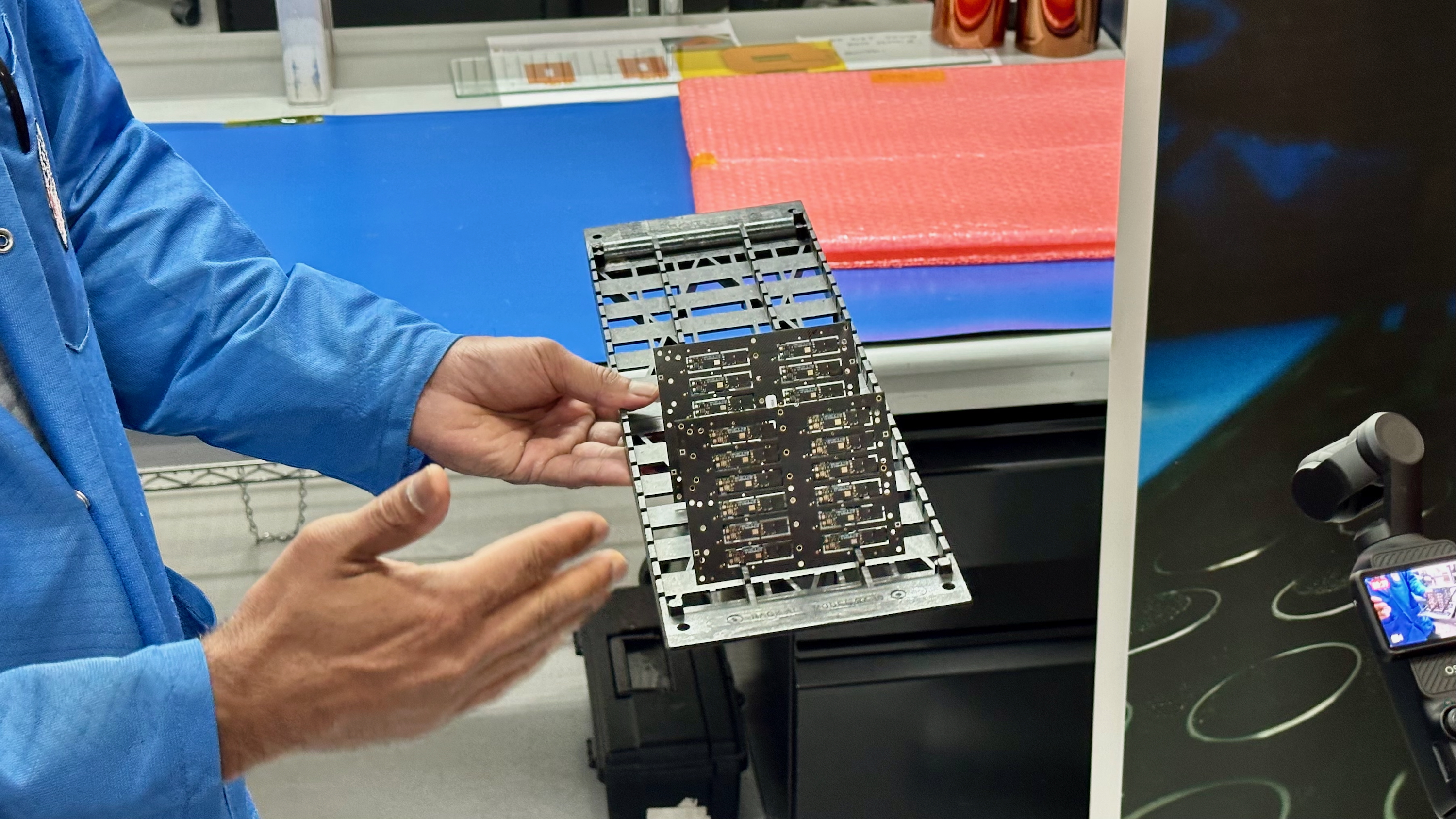

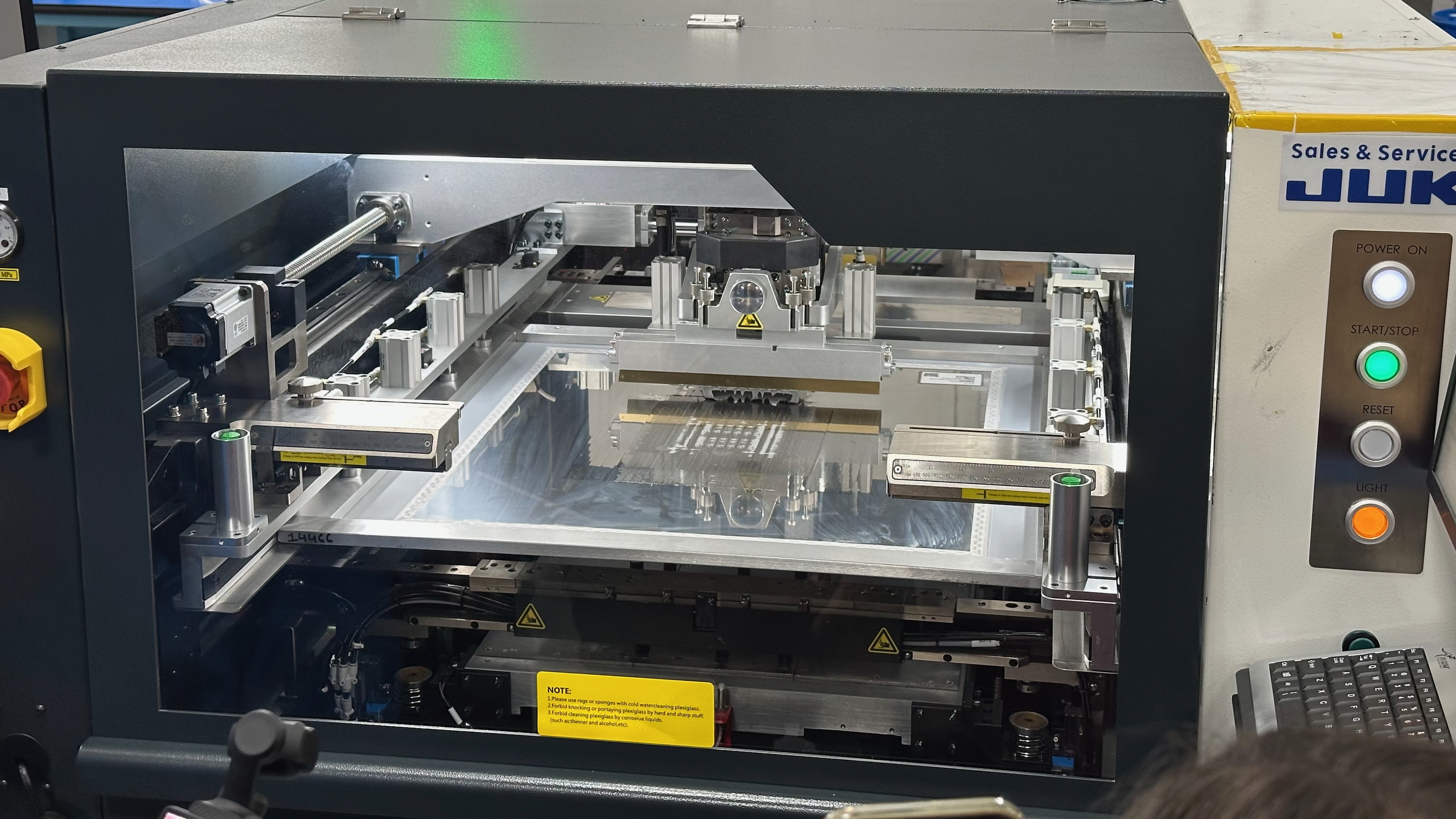

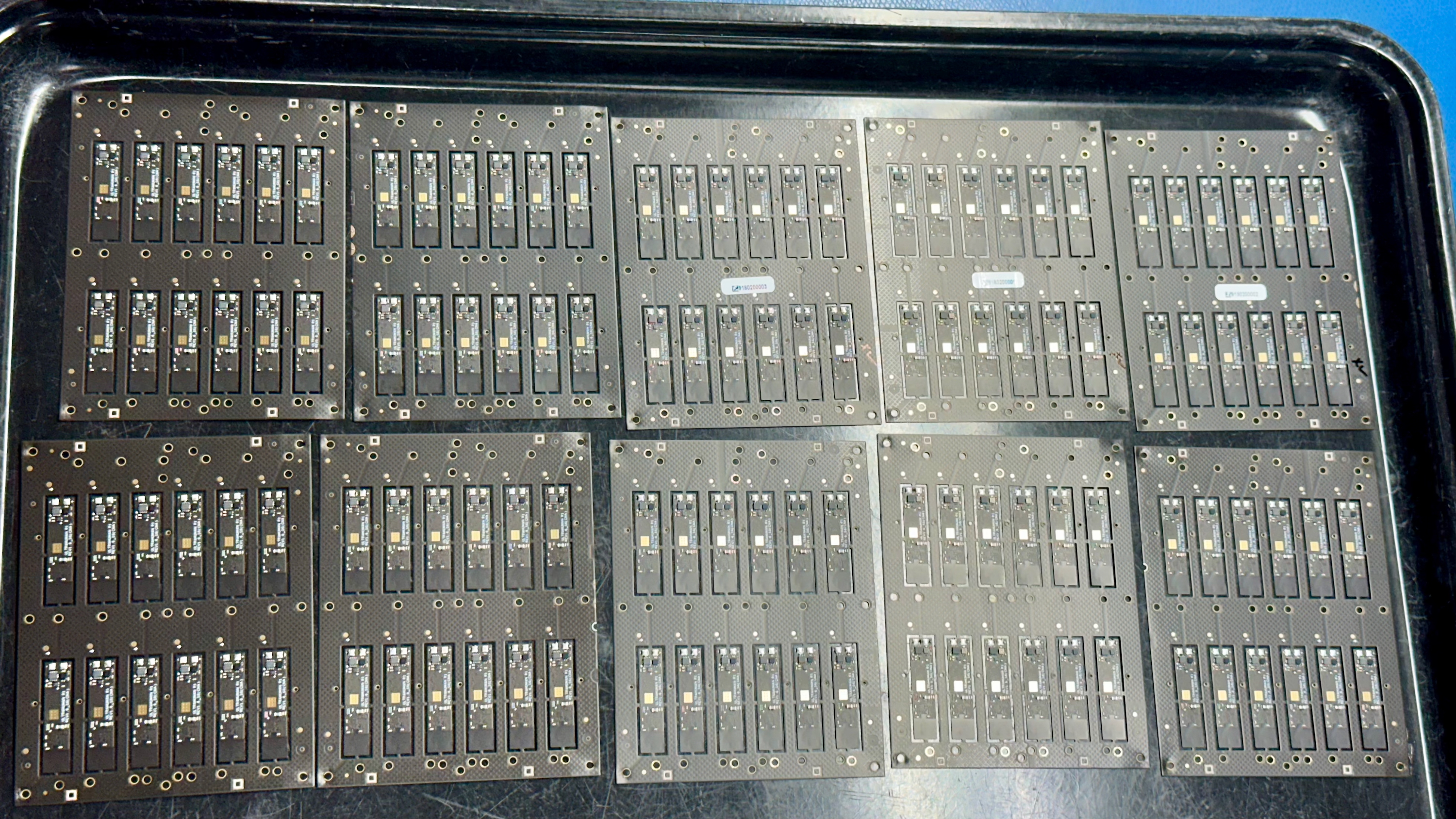

The photograph galleries beneath present practically each step of Ultrahuman’s sensible ring-making course of, beginning with the creation of printed circuit boards (PCBs), which include the SoC, PPG, IMU, temperature, and Bluetooth parts.

These parts are mass-producible — an engineer urged one machine may produce 10,000 PCBs in a day — and fabricated from fiberglass, polyamide, and ceramic supplies, chosen to make them bendable sufficient to slip naturally into the rounded ring form.

However the “UltraFactory” at present solely makes about 400 sensible rings per day, although Ultrahuman has promised to hit about 1,350 per day or 500,000 per 12 months by the top of 2025. There are a number of ache factors, beginning with the truth that the opposite mass-produced parts should be soldered onto the PCB by hand.

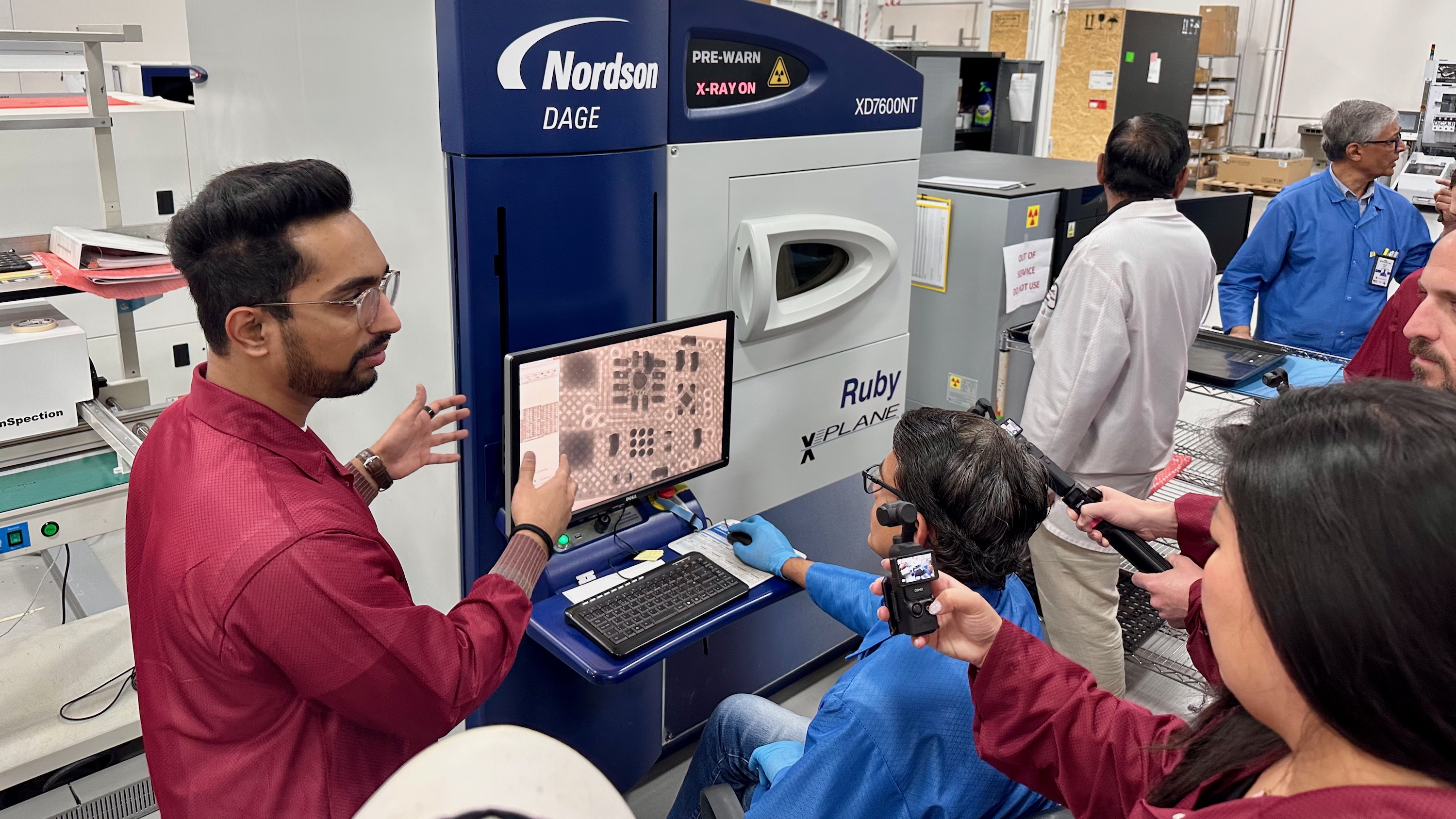

After they create the PCBs, do inside and exterior spot checks for any flaws, and program every PCB with the requisite software program, they’re prepared for the subsequent step: soldering.

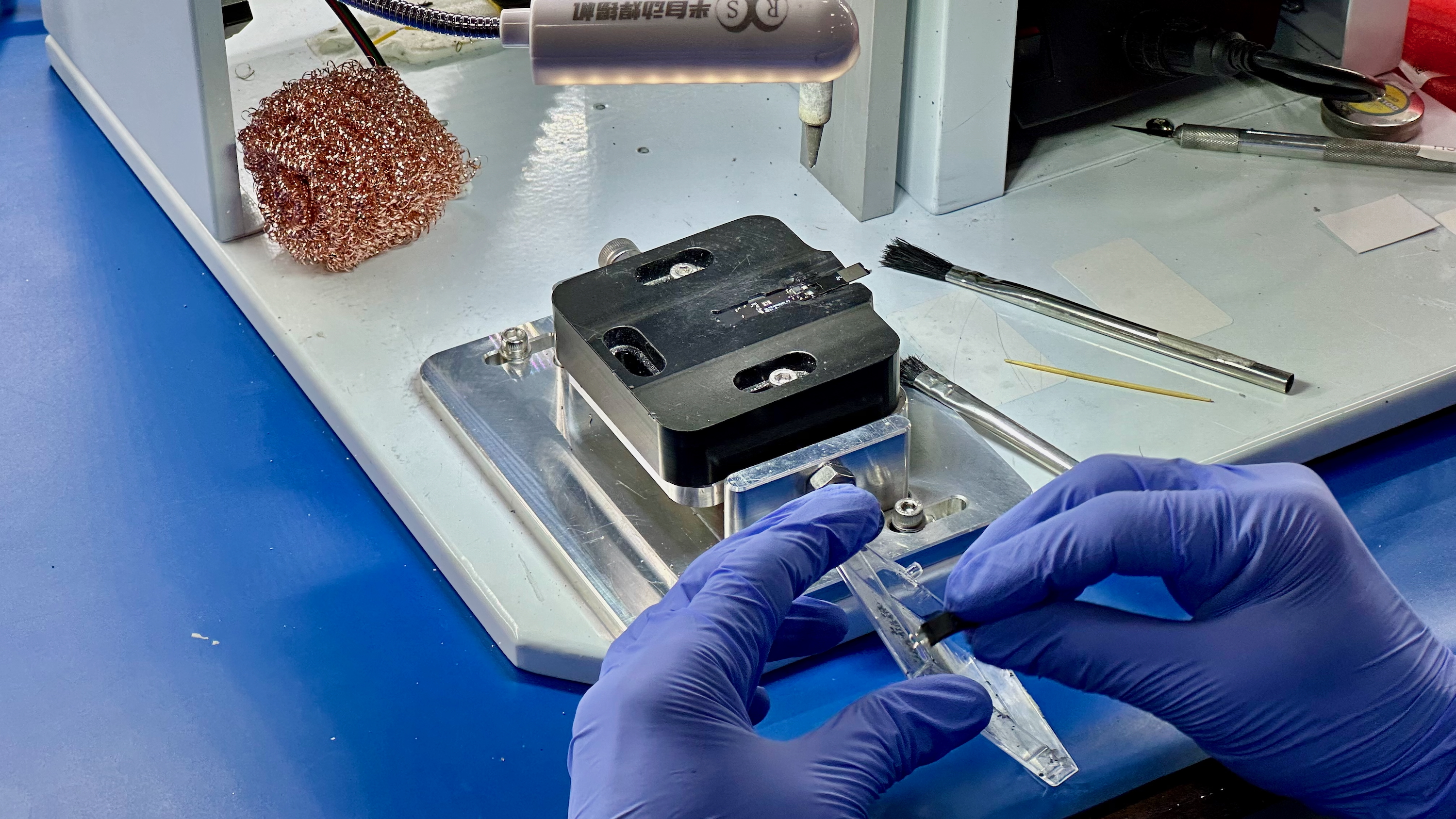

First, the Rx coil is soldered onto the PCB; then, the battery is soldered onto the coil. They brush off the surplus alloy, leaving one seamless, bendable element able to be inserted into the ring.

With a 3D-printed half, the welded-together PCB is curved into a correct J form. The employees then apply glue to the titanium-carbon ring you are acquainted with, take away the quilt for the PCB’s adhesive layer, and at last shove the element into place.

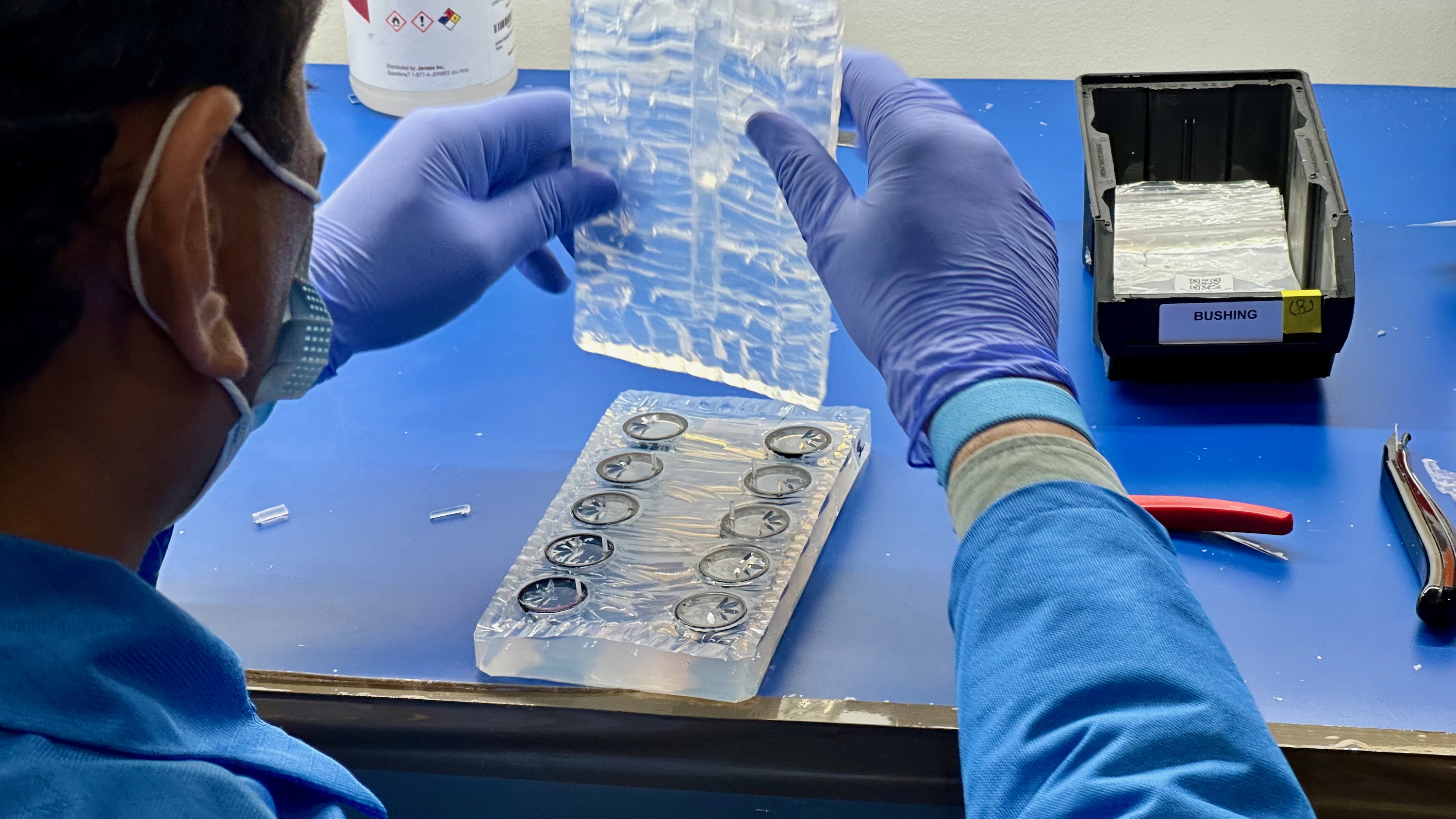

They do a software program examine — since technically, you possibly can put on the ring at this level — after which place the ring inside a silicone mould. One mould with 12 rings is dropped at the casting station, which is one a part of the manufacturing facility the place they would not allow us to {photograph} or report.

There, they inject epoxy resin into the ring from the thickest portion — the PPG — inside a vacuum-sealed chamber to forestall any resin bubbles. The method takes 24 hours, as a result of heating the resin to harden it sooner would injury the parts. Ultrahuman stated this casting course of is without doubt one of the massive ache factors that slows down the ring course of.

At this level, the sensible ring is nearly able to be worn, however the resin will look tough and have onerous edges that’ll damage your finger. They spend about half-hour cleansing and sprucing it into consumer-ready kind.

As soon as that is accomplished, they do yet another software program examine to make sure every thing is as much as code. Then, they place the ring on a 3D-printed half to examine its measurement; if it will not match or slides all the best way down the cylinder, they know it is to not code. In any other case, the Ultrahuman Ring Air is able to be offered!

How I made a sensible ring

In the event you’ve been paying consideration, you may observe that I could not make a sensible ring from begin to end throughout this tour. The 24-hour resin course of made that unimaginable. So it is extra correct to say that I received midway by way of making a sensible ring after which returned a special sensible ring for the ultimate a part of the method. Nor did I get to deal with any software program or {hardware} QC.

I am nonetheless going to say I made a sensible ring, although. They instructed me my halfway-done sensible ring would finally be offered to somebody, and that is fairly neat.

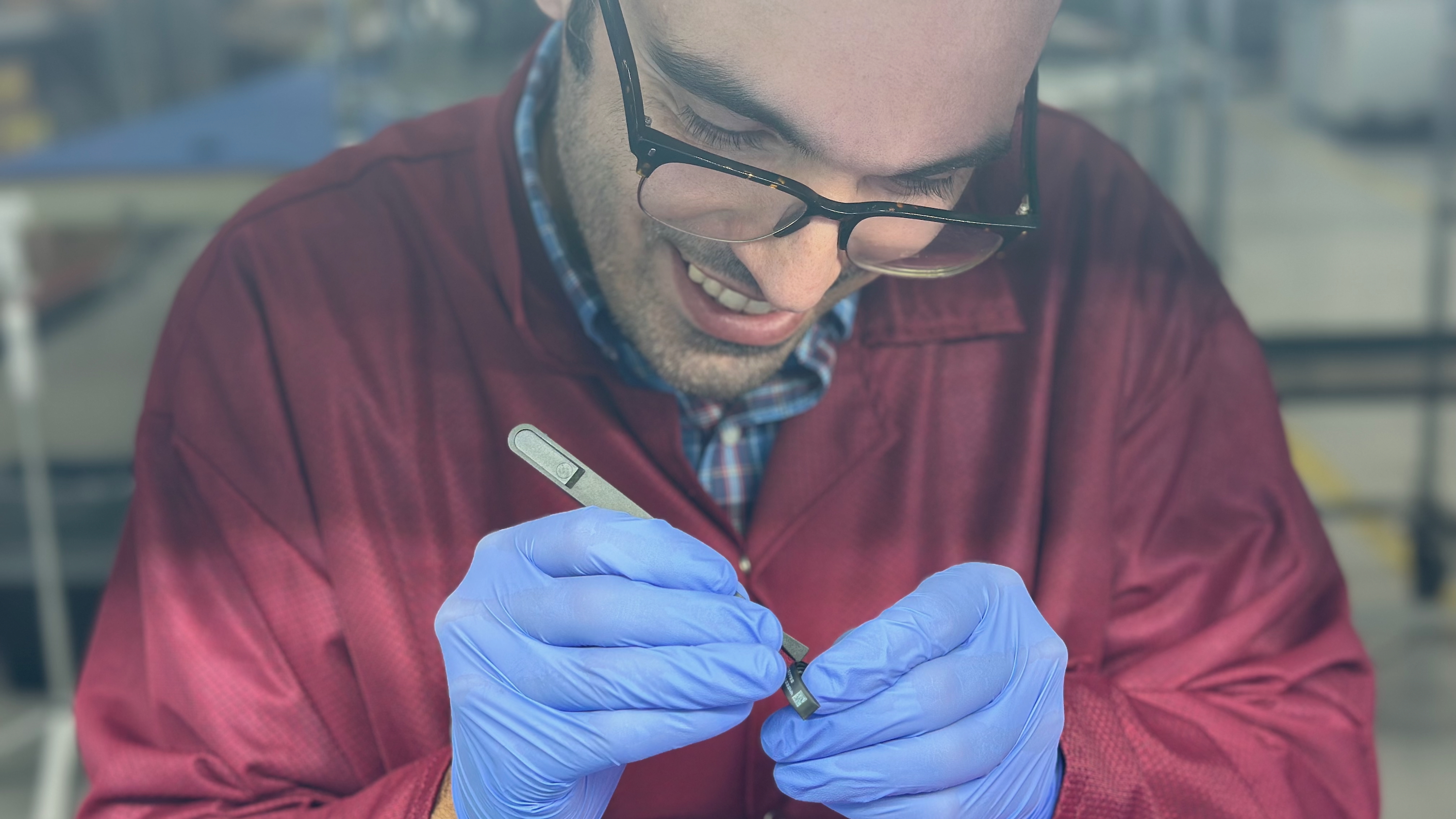

Following the steps above, I soldered the receiver coil onto the PCB by scraping some adhesive onto the coil after which stepping on a swap to set off the machine (with out burning off my thumbnail, fortunately). I then needed to solder two separate factors to connect the battery earlier than brushing away the surplus adhesive.

I curved the Ring Air parts so they’d match inside, ripped off the adhesive with tweezers, shoved them contained in the ring, after which pressed onerous on the sensors to make them stick.

I used to be positive my clumsy, shaking fingers would break one thing, however it turned out my solely subject was being too mild. One portion got here free as I began to shove my sensible ring into the casting mould, however I received it reattached and waved farewell to my ring.

Then they gave me one other ring additional alongside within the course of and had me clear off the resin, utilizing an electrical spinning brush, sandpaper, and a few 3M buffing fluid. I did not get to complete the total 15+ minutes earlier than Ultrahuman workers hustled me alongside to my interview, however I can truthfully say I received that Ring Air into ok form that the resin would not reduce any fingers or look ugly.

How sensible ring manufacturing may change

I requested Ultrahuman’s CEO, Mohit Kumar, and chief enterprise officer, Bhuvan Srinivasan, about sensible ring repairability, a main subject with all sensible rings. The resin that retains parts in place and guarded additionally makes all of it however unimaginable to take rings aside for restore, and there are not any seen buttons for resetting a malfunctioning ring.

They defined that they hope so as to add a tiny, hidden button to their sensible rings. If a Ring Air is shipped in for restore, they will be capable of take away a tiny little bit of resin to carry down that button and reboot the ring right into a mode the place it may well obtain firmware updates.

I requested if they’d any hopes for a extra modular design that might allow them to take away and change a battery, since sensible ring batteries are so small and vulnerable to shedding capability after a few years. Kumar replied that they are interested by it, however I received the sense that it is extra of a pie-in-the-sky objective than one thing they’re actively pursuing for the time being.

For now, they’re extra centered on optimization. As a result of American labor prices are increased than of their Indian facility, they’re seeking to make the method extra environment friendly; for instance, they discovered a brand new casting machine that might inject resin into 4 occasions as many rings without delay, breaking open that bottleneck within the manufacturing facility line.

As for me, I am curious how the manufacturing processes of different sensible rings differ from these of Ultrahuman and the way they’re evolving because the tech improves. However proprietary variations apart, the UltraFactory expertise gave me respect for the quantity of high quality management that goes into making a sensible ring — whereas additionally stunning me that somebody like me with no industrial expertise can undergo the steps with sufficient hand-holding and endurance.