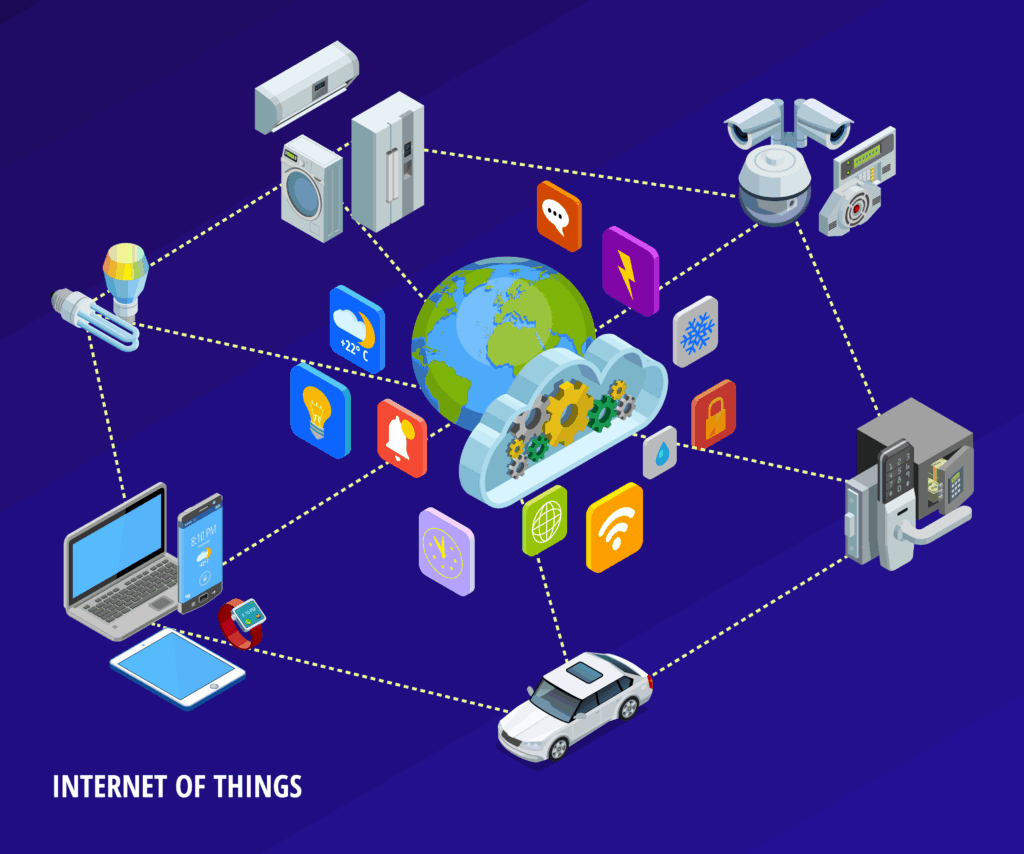

The Web of Issues (IoT) is bringing a digital revolution to the manufacturing trade. By connecting machines, sensors, and techniques by way of the web, producers can now gather real-time knowledge to enhance effectivity, cut back downtime, and streamline operations. As digital expertise and improvements like AI in healthcare are altering different sectors, IoT is turning into a strong instrument for smarter and quicker manufacturing.

What Is IoT in Manufacturing Digital Revolution?

IoT in manufacturing, typically known as Industrial IoT (IIoT), refers to using internet-connected units to watch and handle industrial operations. These units gather and ship knowledge to assist producers make higher choices, cut back waste, and preserve constant product high quality. From machine sensors to automated techniques, IoT helps factories turn into smarter and extra productive.

Advantages of IoT in Manufacturing

1. Actual-Time Monitoring

IoT permits steady monitoring of equipment and gear. If a machine begins appearing abnormally, the system can ship alerts instantly. This helps forestall breakdowns and retains manufacturing on observe.

2. Predictive Upkeep

With the assistance of sensors, producers can detect early indicators of kit points. This implies machines will be serviced earlier than they fail, lowering downtime and upkeep prices.

3. Elevated Effectivity

IoT helps automate routine duties, optimize manufacturing schedules, and handle power utilization. These enhancements result in larger productiveness and decrease operational prices.

4. Higher Stock Administration

IoT units can observe stock ranges in actual time, guaranteeing supplies and merchandise are all the time out there. This reduces delays and avoids overstocking.

5. High quality Management

Sensible sensors can monitor product high quality all through the manufacturing course of. If one thing goes mistaken, it may be detected and corrected rapidly.

6. Improved Employee Security

IoT can detect unsafe working circumstances, reminiscent of excessive temperatures or dangerous gases, and alert staff earlier than accidents occur.

How Digital Know-how and AI Work with IoT Manufacturing?

IoT doesn’t work alone. It’s supported by different digital applied sciences like AI, cloud computing, and massive knowledge. In healthcare, AI is used to detect ailments early. In manufacturing, AI can analyze the large quantity of information from IoT units to foretell issues, recommend enhancements, and make choices quicker than people. Cloud platforms assist retailer and handle this knowledge securely, whereas edge computing permits quicker processing close to the supply.

Actual-World Examples of IoT in Manufacturing

Sensible Factories: Many corporations now use sensible sensors and related machines to watch efficiency and enhance output. These factories regulate operations in actual time to keep away from delays and waste.

Vitality Administration: Factories use IoT techniques to watch and cut back power consumption, serving to each the atmosphere and their finances.

Widespread IoT Challenges in Manufacturing

Whereas IoT provides many advantages, there are some challenges too:

- Excessive Preliminary Prices: Establishing IoT techniques will be costly, particularly for small producers.

- Knowledge Safety: With extra related units, the danger of cyberattacks will increase. Robust safety measures are essential.

- Technical Complexity: Managing and analyzing massive quantities of information requires expert workers and correct coaching.

- Integration Points: Connecting IoT with older machines or totally different techniques will be tough.

What Actually Helps IoT Work Higher in Actual Life?

To get essentially the most out of IoT in manufacturing:

- Begin small with pilot initiatives

- Prepare workers to know and use IoT instruments

- Spend money on knowledge safety

- Work with dependable expertise companions

- Monitor efficiency recurrently and regulate as wanted

Conclusion

IoT is remodeling manufacturing by making it smarter, quicker, and extra environment friendly. With the assist of digital expertise and AI, it helps enhance product high quality, cut back prices, and improve security. Although there are some challenges, the advantages make IoT a strong step towards the way forward for manufacturing. As extra corporations undertake IoT, they’ll achieve a aggressive edge within the digital age.

FAQs

1. What’s IoT in manufacturing?

IoT in manufacturing refers to utilizing internet-connected units to watch and management machines, enhance manufacturing, and cut back waste.

2. How does IoT assist cut back downtime?

Through the use of sensors that monitor machines, IoT can detect points early and ship alerts so issues will be mounted earlier than a breakdown happens.

3. Can small producers use IoT?

Sure. Small producers can begin with easy, low-cost IoT options and increase as they see advantages.

4. Is IoT protected to make use of in factories?

Sure, however sturdy cybersecurity is necessary to guard knowledge and forestall system assaults.

5. How does AI assist IoT in manufacturing?

AI analyzes the info from IoT units to seek out patterns, predict points, and make choices that enhance operations.

6. What industries use IoT in manufacturing?

Automotive, electronics, meals and beverage, and prescribed drugs are among the high industries utilizing IoT.

7. How can IoT enhance product high quality?

Sensors observe product high quality in actual time, serving to spot and repair points rapidly throughout manufacturing.

8. What’s predictive upkeep?

It’s when IoT helps determine early indicators of machine issues so upkeep will be accomplished earlier than a breakdown occurs.

9. Do IoT techniques want web on a regular basis?

Most do, however some use edge computing to work even with restricted web by processing knowledge regionally.

10. What’s the way forward for IoT in manufacturing?

IoT will proceed to develop, with extra sensible factories, higher automation, and deeper integration with AI and digital instruments.

Writer Bio:-

Ritesh Dave is the Co-Founder & Director – Gross sales at Synoverge Applied sciences. A seasoned IT outsourcing chief with 20+ years of worldwide expertise, he excels in enterprise improvement, consumer engagement, and constructing high-value strategic partnerships.